![]()

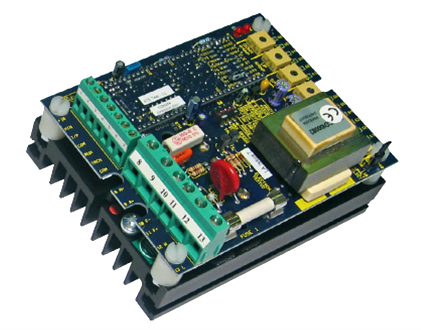

Founded in 1987, Sprint Electric design and manufacture a wide range of range of digital motor control solutions up to 1MW covering both single fase and three phase, regenerative and non-regenerative applications. Models available for DC Motor Control 2Q and 4Q Up to 2250A.

EXTENSIVE RANGE OF APPLICATIONS

Sprint Electric’s innovative DC drive & AC slip ring drive solutions are designed and manufactured to meet the demands of countless industrial motor control applications around the globe. Our products have been designed to increase productivity, save space and reduce downtime.

Our products are designed both for new motor control applications as well retrofitting and upgrading existing applications. Applications include those in the metals, paper, plastic, lifts, hoists, cranes, entertainment, material handling, printing, wire and cable industries.

PRODUCTS

Founded in 1987NFO Drives shall, with good profitability, develop, manufacture and market equipment for speed-regulated control of electrical motors.

NFO Drives is a Swedish cleantech company, which works with developing and manufacturing products that make electrical motors for machines, fans and pumps etc. more energy efficient. With our product – the NFO Sinus frequency inverter – the motor’s speed can be adapted to actual need, which means that you can save up to 70% energy.

A profitable investment

With the NFO Sinus frequency inverter you can control the speed of electrical motors for machines, fans and pumps and save energy. An investment often pays for itself within a year.

Simple Installation

- No shielded cables

- No complicated installation requirement

- No limitations of distance

Silent Operation

- No electromagnetic interference

- No irritating switching noise

Safe Technology

- No bearing currents

- No earth currents

Trio Motion Technology is a specialised source of high performance motion control technology, a field of automation, encompassing the systems involved in moving parts of machines, robots or motors in a precise and controlled manner. The main components involved typically include a motion controller, drives and motors or actuators.

Trio Motion Technology has been manufacturing high-quality motion controllers branded Motion Coordinators since 1987 and has a comprehensive range that allows economical, flexible and seamless control of 1 to 128 axes of servo motors, stepper motors, piezo motors or hydraulic systems. Trio products can be found in virtually every servo and stepper application.

Motion Perfect v4

A single programming interface for motion and machine control up to 128 axes of coordinated motion, Motion Perfect is designed to make setup, diagnostics, commissioning and using our range of Motion Coordinators as simple as possible. Motion Perfect provides the user with an easy to understand Windows based interface for rapid application development, controller configuration and monitoring of controller processes. The integrated UNIPLAY system makes HMI screen development quick and easy.

NEW!

- Robot Tool…Now incorporated into MPv4.

- New and extended functionality in Unilpay HMI…New controls and improvements to existing controls, Direct editing mode added, Extra HMI functionality for robot pendant, styling added to components in HMI designs.

- Additional devices supported… PC-MCAT, MC508, Flexslice EtherCAT I/O system.

- Support for BASIC program libraries

- Enhanced TrioBASIC editor

- Support for user defined functions in TrioBASIC

- Over 100 enhancements and improvements!

TrioBASIC

The TrioBASIC programming language, with a powerful suite of instructions and tools developed over 24 years, makes even the most advanced motion programming easy. TrioBASIC provides ease of programming for many complex applications. With multitasking and subroutine capabilities, it allows users to create modular programs, ideal for code reuse and better readability thus saving valuable time. The syntax is similar to that of other BASIC family languages.

Features

- Fast BASIC language for easy standalone machine programming

- Fully integrated with Trio’s Motion Perfect application development software

- Comprehensive motion control functions for multiple axes

- Multi-tasking of multiple programs for improved software structure and maintenance

- Support for traditional servo or stepper axes as well as modern digital (Sercos, EtherCAT etc) axes

- A comprehensive set of move types supporting multiple axis coordination as well as simple single axis moves.

This includes linear, circular, and spherical interpolation as well as cam profiles and software gearboxes - Real maths (up to 64 bit) including bit operators and variables

- Support for hardware position capture

- Support for high speed outputs

IEC61131-3

The built in industry standard IEC 61131 runtime, is an easy to use full function PLC programming system. The standard is already well established in Europe and is rapidly gaining popularity in North America and Asia as the programming standard for industrial control.

Features

- Standard language can be used by any programmer who is already familiar with IEC 61131-3

- Choice of graphical or textual programming while attaining consistent results

- Visual interactive debugging information

- Real-time program execution

- Powerful and familiar Trio Motion function block library

- Program editor is built-in to MotionPerfect

- Multi-tasking operation with user selectable priorities

TrioRPS

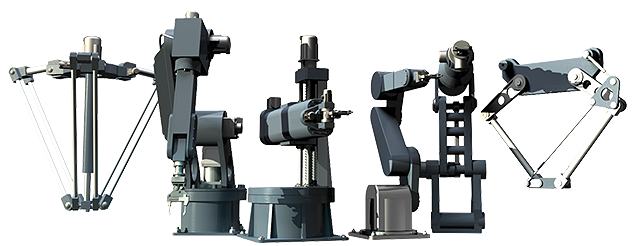

The Trio Robot Programming System or TrioRPS, is an open and adaptable package of tools and software that offers complete control and management of your robot systems.

Overview

The Robot Programming System components include:

- A high level robot programming language building on the fast effective multi-tasking TrioBASIC.

- Kinematics transformations package configurable for the majority of robot mechanism types.

- Robot visualization tool in Motion Perfect v4

- Pendant and teach programming system. This allows programs, robot tools and points to be built, edited and proven in an easy to use way.

- A special robot tool within “Motion Perfect v4” for robot configuration, editing points, frames and tools. Complex programs may also be edited inside MPv4.

Recommended Motion Coordinators:

MC4N, MC664, MC508, PC-MCAT 64

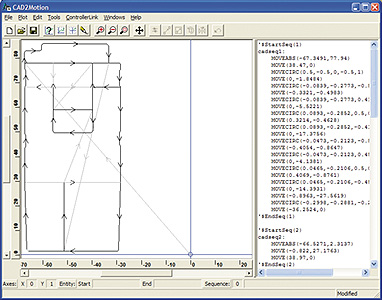

CAD2Motion

CAD2Motion is a program designed to allow users to translate CAD generated two dimensional motion paths into TrioBASIC programs.

The program allows the user to create motion paths in a CAD package such as AutoCAD and convert them into code executable by a Trio Motion Coordinator. Typically the path information will be drawn on a single layer in the CAD package and exported as a DXF file. The DXF file (layer with motion path only) is read into CAD2Motion to create a program to follow the motion path.

The motion path can be manipulated and edited before being saved as a TrioBASIC program file which can be loaded on to a Trio Motion Coordinator.